Krone presented the new generation of Dry Box swap bodies in April 2024, which will begin production in the second half of the year. The new Dry Box series offers about ten advancements in design and functionality designed to increase stability, protection, and ease of use. The swap bodies feature smooth steel walls which are now more durable, and the front wall includes an upper recess to provide additional space and reduce damage risks during cornering maneuvers. Moreover, the collision protection has been extended up to 1,300 millimeters at the bottom, thus improving daily resistance to impacts on the roads.

Another significant update is the addition of embossing on the front and side rails, which not only stabilizes the bodywork but also better protects safety and identification stickers and markings. The corner posts, both at the front and back, have been reinforced and extended to the floor, enhancing the structural integrity of the swap bodies.

For the corner fittings, Krone has introduced an innovative integrated support leg, which drivers will particularly appreciate. The support leg is now more easily accessible and operable from the outside, with a rubber coating that ensures a comfortable grip. The safety closure of the ladder has been improved with the introduction of a spring plate, making it simpler and more intuitive to use.

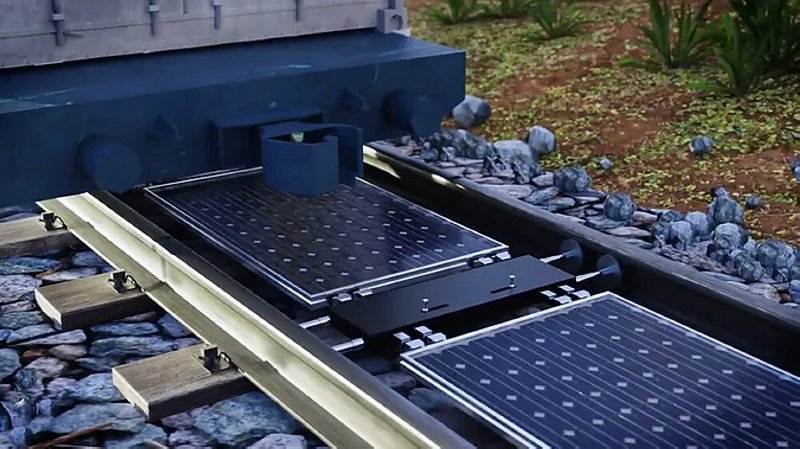

Modifications to the lower part of the Dry Box include an increased tunnel space from 90 to 100 millimeters, allowing greater flexibility and loading capacity. The interior of the swap bodies has also been upgraded: the new threshold protection features embossing on both sides, providing the option to weld an additional anchorage for enhanced load security. Lastly, for rapid loading cycles, a roll-up shutter is available at the rear, compatible with the rail sector, which can be operated directly from the loading ramp, facilitating easier loading and unloading processes.

Massimiliano Barberis