Tesla made its debut at IAA 2024 by showcasing two models of its Semi electric truck, one of which is available for test drives on the exhibition’s internal circuit. Alongside the vehicle, Tesla's stand featured a charging column. While there were no significant technical updates, the spotlight was on Priestley’s presentations on September 17 and 18, where he discussed the operational results from U.S. trials and the company’s strategic plans.

Currently, Tesla operates a fleet of around 100 trucks on U.S. roads, with the majority being used by PepsiCo. Collectively, these trucks have logged 7.5 million kilometers. One vehicle, in particular, has traveled over 400,000 kilometers in just 18 months of operational use under maximum load. Priestley noted that reliability has significantly improved, with the fleet achieving a 95% uptime, meaning the vehicles are operational and free from major breakdowns or maintenance needs.

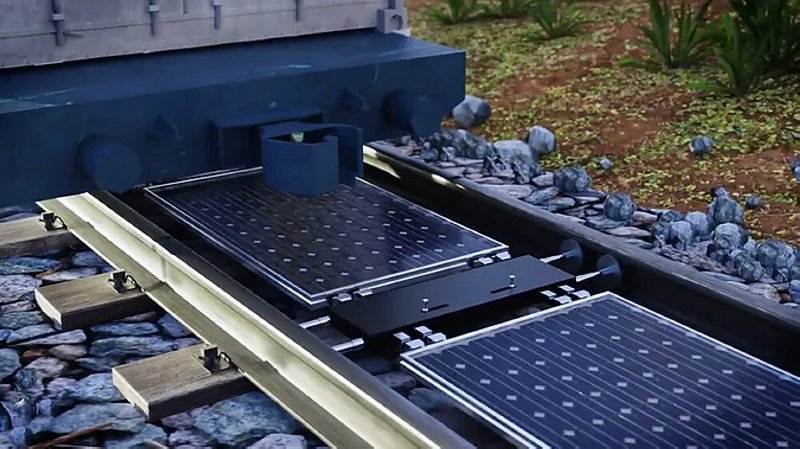

Key concerns surrounding electric trucks involve charging and range. Priestley announced the development of Tesla’s Megawatt charging column for heavy-duty vehicles, which is expected to offer recharging times similar to diesel refueling. He added that the Semi's energy consumption averages 100 kWh per 100 km, making it more efficient than 2024 diesel trucks and slightly superior to other electric trucks on the market.

Regarding charging infrastructure, Priestley highlighted that a Megawatt charging column would be needed for every ten vehicles. However, he pointed out that full charges aren’t always necessary in transport operations, as partial charging (known as "opportunity charging") can take place during loading and unloading or during driver breaks—something diesel trucks cannot do. With the right charging strategy, a Tesla Semi can cover up to 1,700 kilometers in 24 hours.

Priestley also addressed production plans for the Semi. In 2024, Tesla aims to increase production and start mass production by 2025 at its dedicated plant currently under construction in Nevada, with further scaling expected the following year. After solidifying its U.S. production, Tesla plans to enter the European market, likely in 2026 or later, followed by Asia.

Before entering Europe, Tesla will need to adapt the vehicle to meet European Union regulations. However, Priestley clarified that the Semi was designed from the outset to be versatile for various global markets. A prototype already exists that meets EU size requirements and is compatible with European trailer couplings.

Priestley further revealed that Tesla is actively seeking a Business Development Manager for the European market and hinted at potentially introducing a business model similar to the one used with PepsiCo in the U.S.—a turnkey solution that includes the vehicle, charging stations, maintenance, and corporate support.

While no major technical innovations were presented in Hanover, Priestley highlighted recent improvements to both hardware and software. Software enhancements have improved charging curves and vehicle range. On the hardware side, Tesla developed a new chassis to accommodate a sleeper cab and an independent front suspension for the future European version, which also increases regenerative braking capacity.

One event Priestley did not mention in his presentation was an accident that occurred on August 19, 2024, near Emigrant Gap, California, where a Tesla Semi caught fire. Early reports suggest that the vehicle struck a traffic barrier and a tree before sliding down an embankment, where the battery caught fire. While diesel trucks also catch fire, what stood out in this case was that firefighters used approximately 190,000 liters of water to extinguish the flames, closing the road for hours. The National Transportation Safety Board is currently investigating the incident.