To cut costs and boost rail transport efficiency, Kazakhstan and India are piloting double-stack systems, enabling two levels of containers on rail cars. This approach, introduced in the U.S. in 1984, now accounts for 70% of domestic intermodal shipments there. By stacking containers, freight trains can carry nearly twice as many units, significantly lowering transportation expenses.

In the U.S., railroads utilize specialized cars that reduce vertical distance and lower the center of gravity. Additionally, the car design enhances cargo security by preventing the opening of the lower-level container doors, reducing theft risks. In Europe, geographical constraints, numerous bridges, and tunnels limit the use of double-stack systems, but the approach may soon expand in India and Kazakhstan.

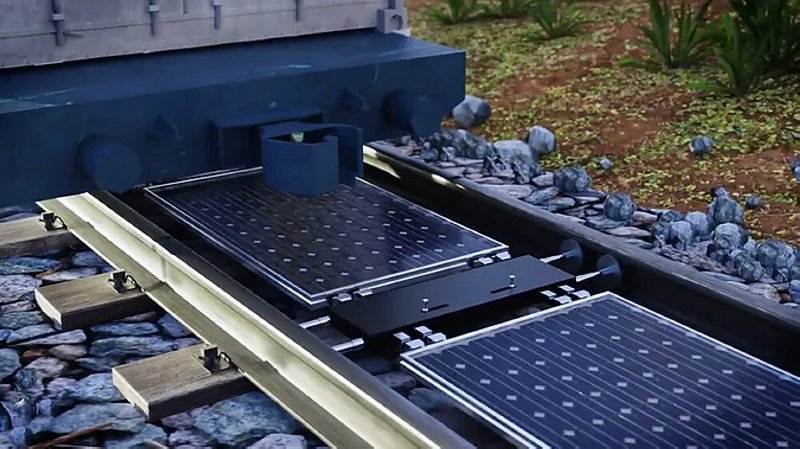

Ktz Express Jsc, a subsidiary of Kazakhstan Railways NC Ktz, has already trialed its first double-stack train, departing from the Altynkol border crossing. The train reached Zhetygen before returning to base, completing approximately 670 kilometers. The project, made possible through collaboration between Ktz Express, terminal operator Ktze-Korgas Gateway, Ktz-Freight Transportation, and rolling stock manufacturer Ziksto, uses cars adapted for this type of transport.

“The main advantage of this technology is improved transportation efficiency, productivity, and mobility. Double-stacking containers allows more goods to be moved in a single journey, reducing logistics costs and accelerating delivery times,” stated Ktz in an official note.

Similarly, the Container Corporation of India Limited (Concor) plans to launch a double-stack container train from Dadri to Varnama within the next two months. This over-1,000-kilometer route will transport 180 TEUs on a single train. Concor’s president, Sanjay Swaroop, noted that containers will initially travel on two single-level trains, be transferred to a double-stack train in Varnama, and continue to Dadri.

This project aims to revitalize Concor’s market position, recently affected by high handling and storage costs and increasing competition, pressures likely to impact its stock value through 2025. Decreased volume has also contributed to Concor’s stock performance decline, which may negatively affect the company’s performance into next year. Enhanced flow through double-stacking should help Concor boost its market image, cut supply chain costs, and mitigate volume downturns, providing the company with greater stability.

Marco Martinelli